Low-Temperature Material Performance of Rackable Plastic Pallets

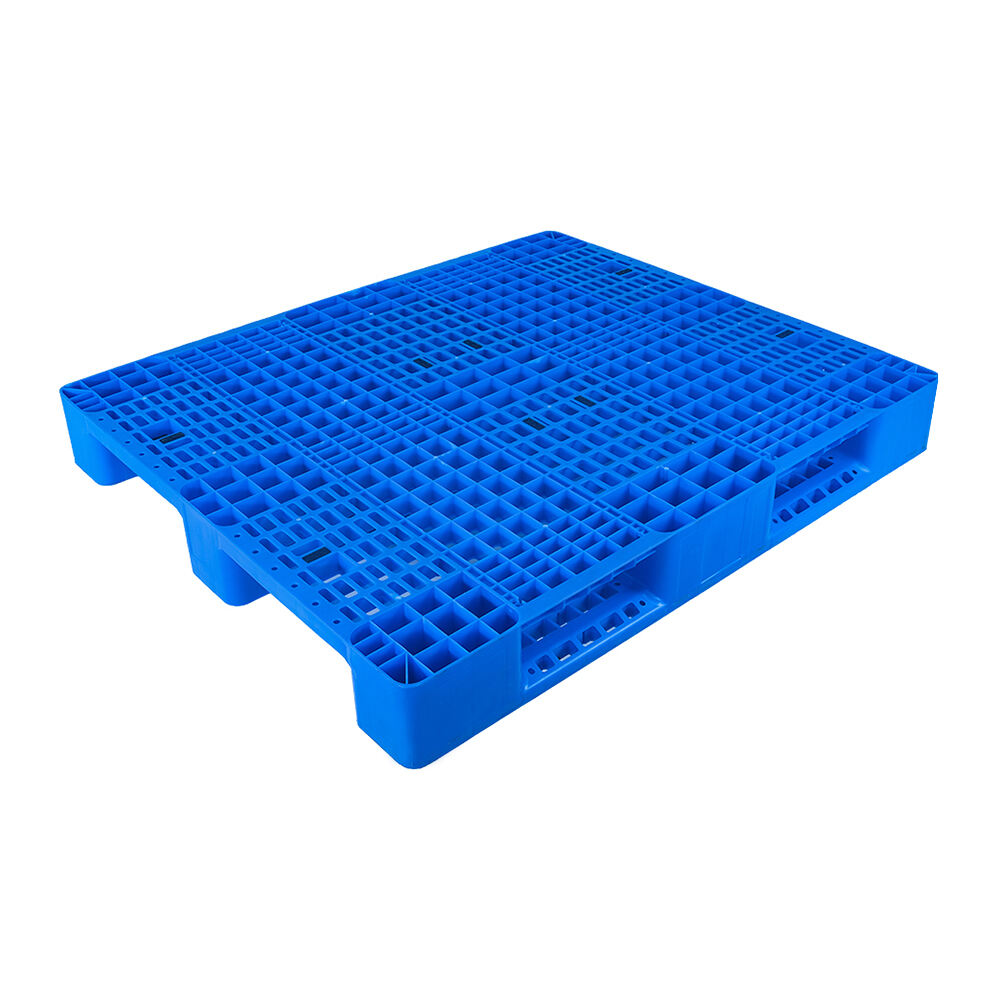

The effectiveness of rackable plastic pallets in cold storage environments is fundamentally determined by how their materials resist brittleness and maintain structural integrity under sub-zero conditions. Material selection directly impacts durability, safety, and long-term reliability in frozen logistics operations.

Brittleness Thresholds: HDPE vs. PP vs. Composite Materials at Sub-Zero Temperatures

HDPE pallets start getting brittle when temps drop below -10 degrees Celsius, which means they're much more likely to crack during normal handling or if something bumps into them. On the flip side, polypropylene stays flexible all the way down to -30C. A study from Polymer Science Review back in 2023 showed that PP maintains impact strength over 50 kJ per square meter even at -20C. Some composite materials made by adding glass fibers to PP can handle even colder conditions. Certain grades of these composites stay ductile below -25C without becoming brittle. HDPE has a brittle point about 20 degrees warmer than PP does, so it just doesn't cut it for really cold storage situations. Sure, composite options give manufacturers some control over thermal properties, but plain old PP remains the go-to choice for warehouse racks in freezer facilities where reliability matters most.

Real-World Impact Resistance: ASTM D792 and ISO 6252 Test Data Below –20°C

Testing materials at cold temperatures gives us a clear picture of how they perform in actual conditions. When we look at PP based rackable plastic pallets through standards like ISO 6252 for impact resistance and ASTM D792 for density measurements, these pallets really stand out. They can handle being dropped from one meter high even when temps hit minus 25 degrees Celsius, and most tests (around 95%) don't show any cracks at all. The situation is quite different for HDPE pallets though. These tend to crack more often, with over 40% showing fractures during similar tests at just minus 15 degrees C according to findings published in Material Testing Journal last year. This contrast highlights why material choice matters so much for cold storage applications.

- PP elongation at break remains above 20% at –20°C, preserving flexibility under load.

- HDPE impact energy declines by 60% below –15°C, sharply elevating failure probability.

These findings confirm PP’s suitability for high-impact frozen distribution, while HDPE is better reserved for milder refrigerated zones where thermal stress is lower.

Structural Integrity and Racking Safety for Rackable Plastic Pallets in Cold Storage

Load Stability Under Dynamic Conditions: 3-Tier Racking Deflection at -25°C

Rackable plastic pallets maintain critical load stability in sub-zero environments, with industry-validated deflection of ±2% under 1,500 kg dynamic loads at –25°C. This level of dimensional control prevents misalignment and supports safe operation in high-density racking systems where forklift maneuverability is constrained. Among material options:

- Composite pallets reduce brittle failure risk by 45% versus standard polymers in ISO 6252 validation.

- While HDPE shows higher impact resistance than PP in ASTM D792 cold tests, its narrower operational temperature window limits practical utility in deep-freeze racking.

Moisture Resistance and Surface Integrity in High-Humidity Cold Rooms

Unlike wood—which absorbs up to 18% of its weight in moisture—rackable plastic pallets eliminate porosity-related failures entirely. This delivers three key advantages in humid cold rooms:

- Zero mold growth potential due to non-porous surfaces

- No condensation-induced load slippage from surface water retention

- Stable mass and geometry, preventing rack misalignment caused by swelling or weight fluctuation

Premium models feature engineered surface coatings that increase coefficient of friction by 60% at 95% relative humidity, enhancing grip during automated retrieval. All validated through 200+ freeze-thaw cycles with no measurable degradation in surface or structural integrity.

Rackable Plastic Pallets vs. Wooden Pallets: Cold-Storage Reliability Comparison

Dimensional Stability, Mold Risk, and Condensation-Induced Slippage in Refrigerated Distribution Centers

How well materials hold their shape when temperatures change matters a lot when choosing pallets for cold storage environments. Wood tends to soak up moisture and can actually warp around 3 percent through those repeated freezing and thawing cycles. This kind of warping messes with how racks align properly, makes loads less secure, and slows down overall operations. Plastic pallets designed for racking systems tell a different story though. These maintain pretty much the same size even when exposed to extreme temps, including long periods at minus 30 degrees Celsius. The reason? Polymers such as polypropylene and high density polyethylene just don't expand or contract much with temperature changes compared to wood.

Mold proliferation presents another critical vulnerability in wood-based systems. Its porous structure retains 15% more moisture than plastic, accelerating microbial growth in high-humidity cold rooms—a documented concern for 78% of food-grade facilities. Plastic alternatives eliminate this hazard outright, meeting hygiene requirements outlined in ISO 22000 for food-safe logistics environments.

Condensation further compounds slippage risks during ambient-to-cold transitions:

- Wooden pallets gain ~12% weight from absorbed moisture, reducing friction on steel rack beams

- Plastic pallets shed surface water instantly, preserving traction and load integrity

Operational data from refrigerated distribution centers confirm these advantages: facilities using rackable plastic pallets report 40% fewer load shifts compared to wood—directly lowering accident rates in high-traffic, temperature-transition zones.

FAQs

What are the temperature thresholds for HDPE and PP pallets?

HDPE pallets become brittle below -10°C, while PP pallets remain flexible up to -30°C, making them more suitable for colder environments.

How does polypropylene perform in impact resistance tests at low temperatures?

PP-based pallets can withstand impacts from a meter-high drop at temperatures as low as -25°C with a 95% success rate of no cracks, as per ISO 6252 and ASTM D792 tests.

What are the advantages of using rackable plastic pallets over wooden pallets in cold storage?

Rackable plastic pallets offer consistent dimensional stability, eliminate mold risk, and prevent condensation-induced slippage, making them more reliable than wooden pallets in cold storage environments.

How do rackable plastic pallets handle moisture in high-humidity cold rooms?

They maintain surface integrity without absorbing moisture, which minimizes mold growth, prevents slippage, and ensures stable load-bearing in humid conditions.

Table of Contents

- Low-Temperature Material Performance of Rackable Plastic Pallets

- Structural Integrity and Racking Safety for Rackable Plastic Pallets in Cold Storage

- Rackable Plastic Pallets vs. Wooden Pallets: Cold-Storage Reliability Comparison

-

FAQs

- What are the temperature thresholds for HDPE and PP pallets?

- How does polypropylene perform in impact resistance tests at low temperatures?

- What are the advantages of using rackable plastic pallets over wooden pallets in cold storage?

- How do rackable plastic pallets handle moisture in high-humidity cold rooms?