Structural Durability of Nestable Plastic Pallets in Long-Haul Transit

Impact, Vibration, and Load Stress Resistance Over 1,000+ km Hauls

Plastic pallets made with High Density Polyethylene HDPE stand up really well during those long distance shipments. These pallets can take quite a beating from moving cargo around and still handle weights over 2500 kg without getting bent out of shape. Wood pallets tend to splinter and crack when forklifts keep moving them back and forth, but these plastic ones stay intact even after being loaded and unloaded more than a hundred times. For trips longer than about 1500 kilometers, special rib designs built into the pallets cut down on vibrations by roughly 40 percent compared to regular rigid models. This means less stuff gets damaged in transport on highways. Real world testing on European roads shows most of these pallets keep working properly even after traveling tens of thousands of kilometers.

Performance Under Temperature Extremes and Humidity: Real-World Weather Resilience

Nestable plastic pallets work great across a wide temperature range, from as cold as -30 degrees Celsius all the way up to 60 degrees. Unlike wood and metal options, they don't warp, corrode, or become brittle when exposed to harsh conditions. The HDPE material these pallets are made from resists moisture so well that they won't swell even when humidity levels reach 85%, which makes them particularly valuable for shipping goods through humid regions like coastal areas or tropical climates. These pallets stay flexible even in freezing temperatures, preventing cracks during transport to Arctic destinations. Tests show that after 300 hours under intense UV light simulating desert conditions, there's basically no sign of deterioration. Exporters in Southeast Asia have noticed something interesting too: their plastic pallets haven't had any weather-related issues over entire year-long operations, whereas wooden pallets get rejected around 27% of the time in similar humid settings. Plus, because these plastic pallets maintain their structural integrity across different temperatures, they help keep adhesives working properly, making them ideal for transporting sensitive items like medicines and perishable foods without worrying about load capacity problems.

Load Stability and Safety Across Multi-Modal Transport Networks

Dynamic Stability on Trucks, Railcars, and ISO Ocean Containers

Plastic nestable pallets offer better load stability when transporting goods via trucks, trains, and standard shipping containers because they reduce movement caused by shifts and vibrations. Made through injection molding, these plastic pallets actually cut down on vibrations by around 43 percent compared to traditional wooden ones, which means fewer accidents where cargo bumps into each other and gets damaged according to the Logistics Material Resilience Report from 2024. The special grooves built into them help soak up those sudden sideways forces that happen when trains change tracks or need to stop quickly, giving better control while still keeping things rigid enough for proper stacking. What's really impressive is how this clever design keeps space between the pallet and container walls even when speeding up, cutting down freight damage by about 19% for long hauls over 800 kilometers.

Slip Resistance and Forklift Compatibility in High-Throughput Distribution Hubs

In high-volume distribution environments, nestable plastic pallets enhance safety and throughput via three core features:

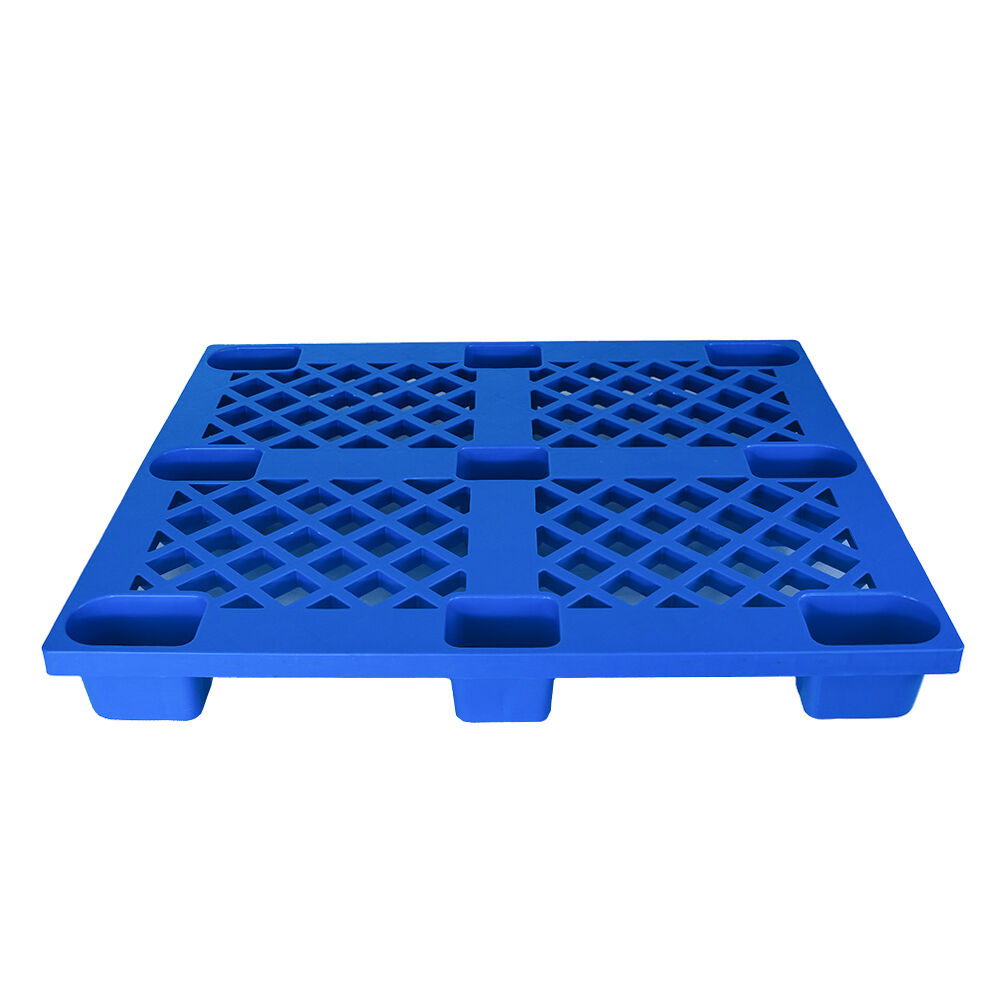

- Non-skid diamond-plate treads sustain a minimum 0.7 coefficient of friction on oily concrete, cutting slip incidents by 31%

- Chamfered leg bases enable rapid, precise engagement with pallet jacks and forklifts—supporting 9-second average cycle times

- Standardized ISO dimensions (1200×800×150 mm) ensure universal compatibility with racking, conveyors, and cross-dock systems

Precision-molded legs distribute weight evenly across container floors and minimize pallet-to-pallet contact during stacking—essential for automated high-bay retrieval systems operating at 30+ pallets per hour.

Logistics Efficiency Gains from Nestable Plastic Pallets

Freight Cost Reduction via 30–50% Weight Savings vs. Wood and Rigid Plastic Pallets

Nestable plastic pallets weigh about 30 to 50 percent less than their wooden counterparts and other rigid plastics too. This makes them great for cutting down on shipping costs because carriers typically charge based on how heavy shipments are. The lighter weight means trucks can carry more goods at once, and studies suggest this can cut fuel usage somewhere around 8 to maybe even 12 percent on those long road trips between cities. When looking at the bigger picture, HDPE plastic lasts much longer than wood and hardly needs any upkeep whatsoever. All these factors together mean companies save money in the long run compared to traditional wooden pallets that break down over time and need constant fixing or complete replacement after just a few years of use.

Space Optimization and Return-Flow Efficiency in Closed-Loop Supply Chains

When empty pallets are designed with this special nesting shape, they can actually stack on top of each other vertically instead of taking up all that space separately. This means warehouses need about 60 to 75 percent less room overall compared to regular pallets that don't nest together. The savings really add up too since stores can fit way more inventory in the same area. For companies running closed loop systems where pallets get returned after use, the compact design makes a huge difference in how things work backwards through the system. Trailers going back from customers can haul around three times as many empty pallets in one trip, which cuts down on those expensive return shipping costs. Getting pallets back into circulation happens faster too, so there's about 25 to 30 percent fewer sitting around doing nothing. Combine this with standard ISO sizes across the board, and everything flows much smoother at cross docking points throughout the whole supply chain network.

Global Regulatory Compliance and Market-Ready Deployability

ISPM-15 Exemption Benefits for Seamless EU, US, and APAC Customs Clearance

Plastic pallets that nest together don't need to worry about those pesky ISPM-15 regulations that plague wooden pallets when shipping into places like Europe, North America, and Asia-Pacific regions. Wood ones have to go through all sorts of treatments first - either heated or fumigated before they can even get near customs checkpoints. The fact that plastic avoids this whole process saves companies tons of headaches. No waiting on paperwork, no getting stuck at inspection points, and definitely no extra fees for certifications. According to some recent numbers from Logistics Compliance Review back in 2023, shipments using plastic pallets typically clear borders about two to three days faster than their wooden counterparts. And it's not just about speed either. These pallets are made from high density polyethylene, which means they won't absorb moisture or harbor pests, making them much easier to clean and maintain over time.

- Sanitary standards for food and pharmaceutical shipments

- Global biosecurity mandates prohibiting wood-boring pests

- Material traceability requirements for supply chain audits

Without mandatory fumigation documentation, companies achieve faster throughput at major ports— including Rotterdam, Los Angeles, and Singapore— enabling reliable just-in-time delivery and minimizing customs-related disruptions.

Frequently Asked Questions

What are the main materials used for plastic pallets?

High Density Polyethylene (HDPE) is commonly used, providing durability and resistance in various conditions.

How do plastic pallets improve transport efficiency?

Plastic pallets reduce vibrations, offer better load stability, and are lighter, reducing shipping costs and fuel usage.

Are plastic pallets suitable for extreme weather?

Yes, they perform well in temperatures ranging from -30°C to 60°C and are resistant to humidity and UV light damage.

What are the benefits in high-throughput environments?

They have non-skid surfaces and chamfered legs for better equipment handling and standardized dimensions for equipment compatibility.

Do nestable plastic pallets comply with global regulations?

Yes, they are exempt from ISPM-15 regulations, aiding in quicker customs clearance in the EU, US, and APAC regions.