Design and Structural Advantages of Double Face Plastic Pallets

What Is a Double Face Plastic Pallet and How Does It Differ from Other Types?

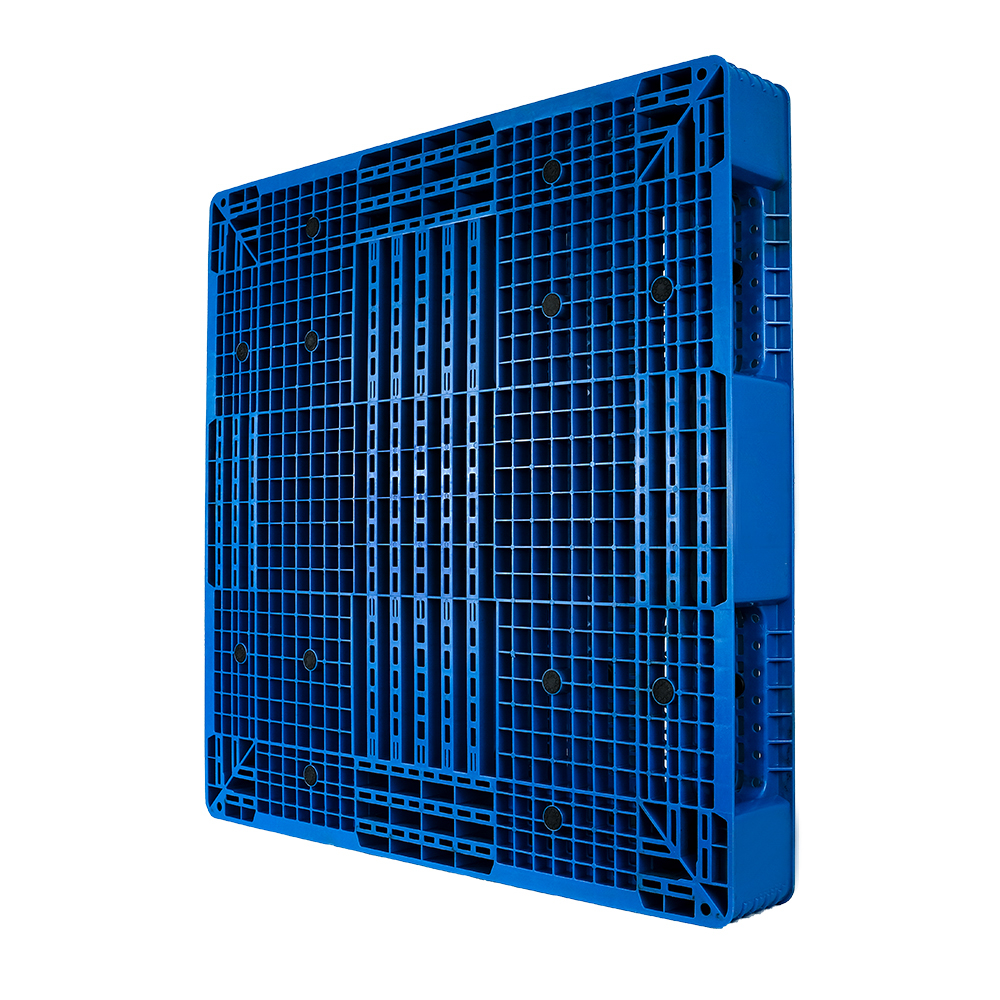

Double face plastic pallets come with load bearing surfaces on both sides, so they can be stacked evenly and accessed by forklifts from any direction. Regular single face pallets only work on one side, while those nine leg models are mostly seen carrying lighter goods for export purposes. The balanced construction of double face options gives much better support when dealing with really heavy stuff in industrial settings. Warehouse managers love these because they handle massive volumes day after day without breaking down, which is why we see them everywhere in places like auto factories and big manufacturing plants where constant movement of materials is part of daily operations.

Structural Features of Double-Sided HDPE Plastic Pallets for Enhanced Load Distribution

Made with high density polyethylene or HDPE for short, these pallets can hold static loads of around 5,000 kilograms and manage dynamic weights up to about 1,500 kg. The design includes reinforced ribs that make them stable, plus those anti slip surfaces help keep cargo from moving around during transport. And because they're made with UV stabilized materials, they won't degrade even when stored outside for long periods. Some recent tests in material handling showed something interesting too. Pallets with central support beams in their rackable designs spread weight better than wood options, improving load distribution by roughly 40%. This makes a real difference in automated warehouses where even small amounts of deflection can cause problems for precision operations.

Material Composition and Manufacturing Process of Durable Double Face Plastic Pallets

HDPE's non porous surface means it doesn't soak up moisture or let microbes take hold, which is why so many companies in food handling and pharma rely on it for their storage needs. When manufacturers use injection molding techniques, they get these smooth single piece containers that don't have those problem areas like wooden crates do with their nails and seams. Plus there's another neat feature worth mentioning here too. The same molding process makes it possible to embed RFID chips right into the container walls during production. That lets warehouses track products throughout the entire shipping journey while still keeping everything clean and strong enough to handle rough transport conditions.

Comparison of Double Face vs. Single Face Plastic Pallets in Industrial Use

| Feature | Double Face Plastic Pallets | Single Face Plastic Pallets |

|---|---|---|

| Load Capacity | Up to 5,000 kg (static) | Up to 2,500 kg (static) |

| Reusability | 8–10 year lifespan | 5–7 year lifespan |

| Optimal Use Case | Heavy machinery, rack storage | Retail distribution, light export |

| Maintenance Cost | 30% lower (no surface replacements) | 45% higher (frequent deck rotations) |

Logistics performance reports indicate that automotive plants switching to double face pallets reduced pallet-related downtime by 62%, demonstrating their superior return on investment in demanding environments.

Hygienic and Safety Benefits in Sensitive Industries

Why Hygiene and Ease of Cleaning Make Double Face Plastic Pallets Ideal for Food Processing

Double sided plastic pallets work really well in food processing plants because their smooth surfaces don't trap bacteria or food particles. These pallets hold up to the harsh cleaning routines common in kitchens and processing areas, surviving both high pressure washes and strong disinfectants without bending or breaking down. Wood pallets just aren't cut out for this kind of treatment they tend to rot over time and soak up all sorts of nasty stuff. According to recent food safety audits across multiple facilities, switching to plastic has cut down cross contamination incidents somewhere around 35-40% in most cases. For food processors concerned about hygiene standards, this makes a real difference in daily operations.

Application in Pharmaceuticals: Meeting Strict Sanitation and Contamination Control Standards

In pharmaceutical settings, these pallets meet stringent requirements including USP <800> guidelines and compatibility with autoclave sterilization. Their resistance to harsh disinfectants and dimensional stability help maintain airtight seals in cleanrooms, ensuring product integrity throughout transport and storage.

Reducing Microbial Growth with Non-Porous Double Face Plastic Surfaces

HDPE’s impermeable surface inhibits biofilm formation, a common problem in damp environments. Independent lab testing shows microbial counts remain 85% lower on plastic pallets after repeated cleaning cycles, underscoring their long-term hygiene advantages.

Increasing FDA and HACCP Compliance Using Hygienic Double Face Plastic Pallets

Integrated traceability features such as RFID tags and certified material documentation streamline adherence to FDA and HACCP regulations. Facilities transitioning from wood to plastic report 30% faster audit completion times, according to 2023 logistics compliance findings.

Industrial and Logistics Applications in Automotive and Manufacturing

Durability Under Heavy Loads: Double Face Plastic Pallets in Automotive Logistics

With reinforced HDPE ribs and dual-load-bearing decks, these pallets handle over 2,500 lbs (1,134 kg), making them suitable for transporting engine blocks, transmissions, and battery packs. Their symmetrical construction prevents warping under uneven loads—an essential feature for oversized components like axles and stamped metal parts.

Integration into Automated Material Handling Systems with Consistent Dimensional Accuracy

Double face plastic pallets are popular among manufacturers because they maintain very tight dimensional tolerances around ±1.5 mm. This makes them work well with robotic arms and conveyor systems without any issues. Most commonly used sizes follow the standard 48 inch by 40 inch GMA specifications which fit nicely into automated guided vehicle operations. Factories report about a 27 percent drop in manual handling mistakes when these pallets are used in automotive production lines. Plus, the surfaces have been designed to prevent slipping, so there's added protection against accidents even when materials move at fast speeds through the facility.

Reducing Downtime Due to Pallet Failure in High-Throughput Production Lines

Plastic pallets eliminate issues caused by splinters, loose nails, and corrosion associated with wood—factors contributing to 14% of unplanned downtime in automotive logistics (Material Handling Institute, 2023). Their one-piece molded design withstands repeated impacts from forklifts and lasts 8–10 years in daily cross-docking operations.

Optimizing Warehouse Efficiency with Reusable Double Face Plastic Pallets

Each double face plastic pallet replaces more than 50 disposable wood units over its lifecycle, cutting restocking needs by 80%. Their nestable configuration achieves a 3:1 stacking ratio, saving 60% floor space during return transport—supporting just-in-time inventory practices across automotive supply chains.

Sustainability, Reusability, and Environmental Impact

Reusability of Double Face Plastic Pallets: Lowering Waste and Total Cost of Ownership

Double sided plastic pallets are built specifically for reuse in logistics systems, cutting down on waste by roughly 85% when compared to those one time use wooden options most companies still rely on. These durable plastic versions can handle well over 200 trips before showing any signs of wear and tear, which means businesses spend about 60% less money replacing them every five years or so. Take the big auto parts manufacturers for instance many of them reported saving around 40% each year on their pallet expenses once they switched to these reusable models. This kind of cost saving also happens to fit right into the broader picture of circular economies where resources get used multiple times rather than ending up in landfills after just one trip.

Lifespan Comparison: Double Face Plastic Pallets vs. Wooden Pallets in Long-Term Operations

In most industrial settings, double face plastic pallets typically last between 10 to 15 years, which is roughly three to four times what we see with wood versions. Plastic doesn't absorb moisture so it won't rot or splinter like wood does, something that actually accounts for around 70 percent of all wooden pallet failures according to the Logistics Efficiency Report from 2023. The longer lifespan means companies spend about half as much on maintenance over time and experience far fewer interruptions during operations. This becomes particularly important when dealing with temperature-controlled storage where even small issues can lead to significant problems.

Recyclability and Carbon Footprint Reduction in Closed-Loop Supply Chains

When HDPE materials reach their end of life, around 95% gets recycled back into things like pallets and other industrial products. This helps slash the need for new plastics somewhere in the range of 8.2 million metric tons each year. Companies that switch to closed loop systems see a pretty significant drop in carbon footprints too about 33% less than what they would get with single use alternatives. Most businesses find that investing in reusable packaging pays off pretty quickly, often seeing returns on investment within two years thanks to lower costs for buying materials and getting rid of trash.

Performance and Adoption Trends Across Modern Supply Chains

Durability in Extreme Conditions: Resistance to Moisture, Chemicals, and Temperature Swings

Double sided plastic pallets hold up well even when temps drop below freezing or climb past 60 degrees Celsius. They won't rust or rot no matter how much chemical exposure they get, which is why warehouses love them for storing stuff in damp conditions. Some recent research from last year showed that switching from wooden pallets cut down on water damaged goods by almost half. The reason? These pallets are made from HDPE plastic, which stands for high density polyethylene. This material doesn't react with anything, so they're great for moving around harsh chemicals or transporting foods that need special handling. That's why so many factories in both the chemical processing sector and food production lines have started replacing their old wooden stock with these durable plastic alternatives.

Consistent Performance in Rack and Floor Storage Environments

These pallets come with special non-slip surfaces and spread weight evenly across the surface, so they don't slide around when stacked high. The measurements are pretty exact too, within about 2 millimeters, which means they work well with those automatic rack systems many warehouses have installed nowadays. Facilities that rely on this kind of automated equipment find them much more dependable overall. According to Occupational Safety Quarterly from last year, workplaces using these stable pallet designs saw roughly 34 percent fewer accidents related to wobbly or tipping pallets. Makes sense really, since keeping things steady prevents all sorts of mishaps on the factory floor.

Growing Use in Cold Chain Logistics Due to Thermal Stability of Double Face Plastic Pallets

The growing need for transporting goods at controlled temperatures has led many companies to turn to plastic pallets because they hold up better in freezing conditions than materials such as polypropylene which tends to crack. The smooth surface of these pallets stops ice from forming and keeps contaminants from getting trapped, something that matters a lot when shipping frozen foods or biopharmaceutical products that must meet strict FDA requirements. A major drug company saw its problems with temperature fluctuations drop by almost half once they made the switch to plastic pallets according to recent industry research published last year.

Industry Case Studies: ROI and Effectiveness in Food, Pharma, and Automotive Sectors

Automotive manufacturers reported 22% faster line feeding cycles thanks to consistent pallet dimensions in robotic systems. In pharma, a European distributor saved $18,000 monthly by eliminating porous wooden pallets. Across industries, companies achieve an average ROI within 14 months due to reduced replacements and waste, according to the 2024 Supply Chain Optimization Report.

FAQ

What are the advantages of using double face plastic pallets over single face ones?

Double face plastic pallets offer higher load capacity, are more reusable, and have a longer lifespan compared to single face ones. They also reduce maintenance costs significantly.

How do double face plastic pallets benefit the food processing industry?

Their smooth surfaces prevent bacteria or food particles from becoming trapped, making them ideal for hygienic environments. They also withstand harsh cleaning routines without breakdown.

Are double face plastic pallets environmentally friendly?

Yes, they are recyclable, reduce waste, and lower carbon footprints, especially when used within closed-loop supply chains.

What material composition provides double face plastic pallets with their durability?

They are primarily made of HDPE (high-density polyethylene), which provides durability, resistance to moisture, and an impermeable surface that reduces microbial growth.

Table of Contents

-

Design and Structural Advantages of Double Face Plastic Pallets

- What Is a Double Face Plastic Pallet and How Does It Differ from Other Types?

- Structural Features of Double-Sided HDPE Plastic Pallets for Enhanced Load Distribution

- Material Composition and Manufacturing Process of Durable Double Face Plastic Pallets

- Comparison of Double Face vs. Single Face Plastic Pallets in Industrial Use

-

Hygienic and Safety Benefits in Sensitive Industries

- Why Hygiene and Ease of Cleaning Make Double Face Plastic Pallets Ideal for Food Processing

- Application in Pharmaceuticals: Meeting Strict Sanitation and Contamination Control Standards

- Reducing Microbial Growth with Non-Porous Double Face Plastic Surfaces

- Increasing FDA and HACCP Compliance Using Hygienic Double Face Plastic Pallets

-

Industrial and Logistics Applications in Automotive and Manufacturing

- Durability Under Heavy Loads: Double Face Plastic Pallets in Automotive Logistics

- Integration into Automated Material Handling Systems with Consistent Dimensional Accuracy

- Reducing Downtime Due to Pallet Failure in High-Throughput Production Lines

- Optimizing Warehouse Efficiency with Reusable Double Face Plastic Pallets

- Sustainability, Reusability, and Environmental Impact

-

Performance and Adoption Trends Across Modern Supply Chains

- Durability in Extreme Conditions: Resistance to Moisture, Chemicals, and Temperature Swings

- Consistent Performance in Rack and Floor Storage Environments

- Growing Use in Cold Chain Logistics Due to Thermal Stability of Double Face Plastic Pallets

- Industry Case Studies: ROI and Effectiveness in Food, Pharma, and Automotive Sectors

-

FAQ

- What are the advantages of using double face plastic pallets over single face ones?

- How do double face plastic pallets benefit the food processing industry?

- Are double face plastic pallets environmentally friendly?

- What material composition provides double face plastic pallets with their durability?