Structural Design and Build: Double Face vs. Single-Face Plastic Pallets

Core Components of Double Face Plastic Pallets: Understanding the Twin-Deck Design

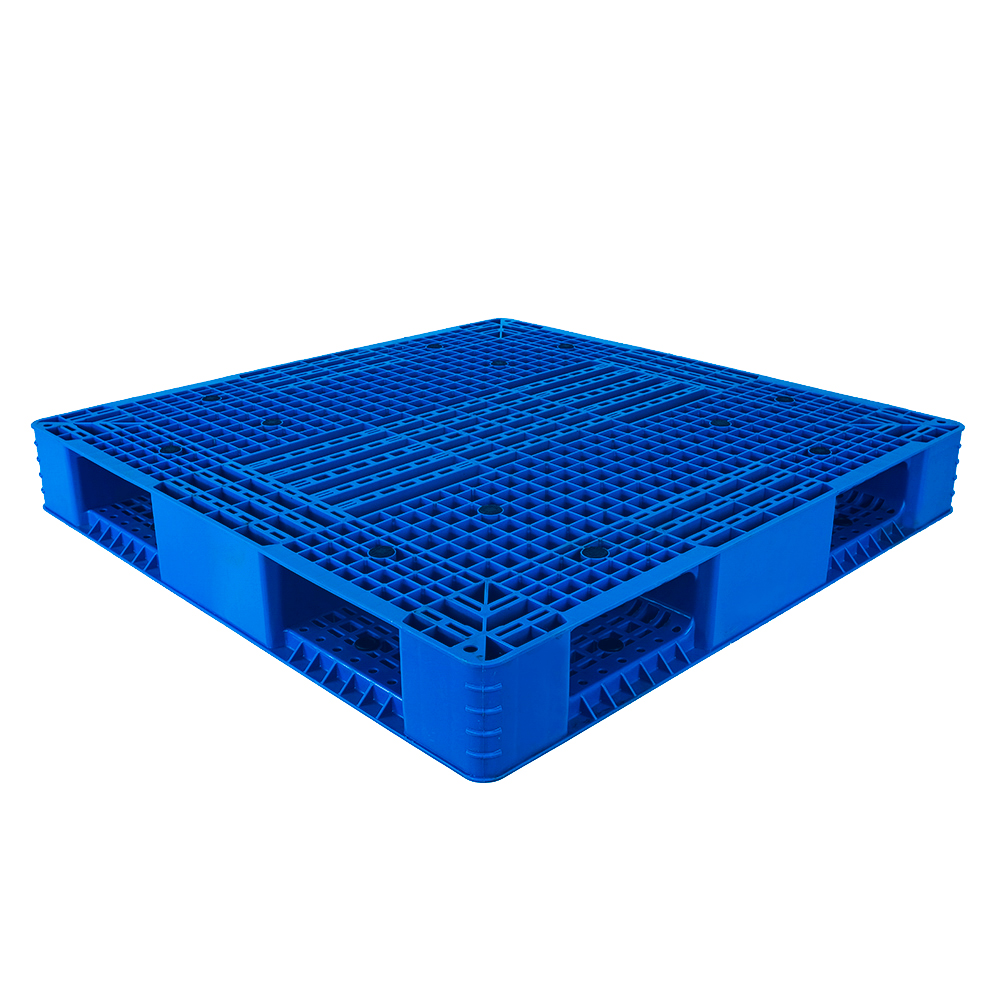

Double face plastic pallets have what's called a twin deck setup, basically meaning there are parallel support beams running between two solid platforms on either side. These differ from their single face counterparts which only have one top surface. The main advantage comes from how these double faced pallets spread out weight across both decks instead of concentrating it all on one spot. According to some industry research looking at different storage solutions, this kind of construction cuts down point stress by around 40 percent when compared to regular single face models. That makes them particularly good for handling heavier items or those that aren't perfectly balanced during transport and storage.

Structural Comparison: How Double-Face Models Enhance Load Support and Rigidity

Adding a bottom deck to double face plastic pallets completely changes how they handle weight. Single face pallets basically depend on just their top surface for support, but when we get those double face ones, they form something closer to a box shape which makes everything much sturdier. Tests done by third parties show these double face models can take around 2,200 kilograms of moving weight before failing, which is roughly 70 percent better than what single face versions manage. For warehouses running automation systems, this extra durability really counts because the pallets need to survive constant picking up and putting down day after day without warping or breaking apart under stress.

Material Composition and Manufacturing Techniques for Long-Term Durability

Double face plastic pallets get their strength from HDPE mixed with UV stabilizers and those slip resistant additives that manufacturers inject into the material. When making these pallets, the way polymers line up during molding creates these interlocked molecular structures that really boost how well they stand up to impacts. According to what the industry has seen, these reinforced pallets hold onto about 92 percent of their original strength even after being reused over 1,200 times. That's actually three times longer than what single face pallets last under similar conditions around warehouses and distribution centers.

Load Capacity, Strength, and Performance Under Stress

Engineering Weight Distribution in Double Face Plastic Pallets

Double face plastic pallets spread weight better because of their twin deck design that works equally well on top and bottom surfaces. Single face pallets tell a different story though most of the stress ends up on those support legs when things are just sitting there according to industry data from 2023. What makes double face models stand out is how they deal with awkwardly shaped items in warehouses that use automation systems. Tests show these pallets manage such cargo about a third better than alternatives. Plus warehouse shelves bend less too something that matters a lot when dealing with heavy goods over time.

Static and Dynamic Load Limits: How Double-Face Designs Outperform Single-Face Variants

Tests show that double face plastic pallets can handle about 2,800 kg when stationary, which is way better than the 1,650 kg limit of single face ones. That's roughly a 70% boost in capacity, something really important for industries dealing with heavy metals or chemicals. When it comes to movement and handling, these twin deck structures hold up remarkably well too. After being moved around by forklifts 5,000 times, they retain nearly 98% of their original strength. Single face pallets don't fair so good, showing about 63% wear and tear under similar conditions. The reason behind this difference lies in those clever interlocking crossbars built into the design. These components actually soak up about 41% more impact energy while transporting goods, making them much more durable over time.

Real-World Performance: Load Testing Results From Industrial Warehouse Trials

An evaluation lasting twelve months across several automotive parts warehouses found that these double-sided plastic pallets held up under 11.2 metric tons of total weight without any bending or warping. That's actually 3.5 times better than what most reusable platforms typically handle in the industry. The way they distribute pressure evenly throughout makes a big difference too. Facilities using them reported 92% of their palletized truckload shipments arriving in perfect condition, which beats the performance of regular single-faced pallets by almost 30%. Warehouse staff have noticed something else interesting as well. Since switching to these twin deck designs, there have been about 57% fewer problems related to damaged loads during handling and transport.

Durability, Lifespan, and Reusability in Industrial Applications

Resistance to Impact, Moisture, and Chemicals: Advantages of Double-Sided Construction

Double sided plastic pallets really hold up well in tough industrial settings thanks to their two level construction. These designs offer protection all around from bumps and knocks plus they resist damage from chemicals too. According to some recent testing published in the APAC Report last year, these dual faced models can take about 40 percent more force before breaking compared to regular single face options. Plus they stay strong even when exposed to humidity or corrosive substances for extended periods. What makes them so good? The way they're molded creates no gaps or corners where water might get trapped or solvents build up over time. This matters a lot in places like pharmaceutical labs and food factories where cleanliness standards are extremely high.

Lifecycle Analysis: Average Reuse Cycles of Double Face vs. Single-Face Pallets

According to 2023 data from the APAC Material Handling Consortium, double face plastic pallets average 127 reuse cycles before requiring repair—triple the lifespan of single-face models. This durability aligns with findings from global reuse initiatives showing that reinforced designs reduce replacement costs by 62% over five years. Key longevity factors include:

- Uniform weight distribution across both decks

- Anti-slip texture minimizing product shift during transport

- Cross-bracing that prevents fatigue-induced warping

Are Double Face Plastic Pallets Over-Engineered for Light-Duty Use?

While double-face models carry a 15–20% upfront cost premium, they prove cost-effective even in light-duty scenarios. A 2022 warehouse audit revealed that double-face pallets used in e-commerce fulfillment centers required 73% fewer replacements than single-face units over three years, despite handling sub-800 lb loads.

Maintenance and Repair: How Design Affects Longevity

Double face plastic pallets are built in modules which means when something breaks, we don't have to throw away the whole thing. If a deck panel gets damaged, it can usually be replaced within about 15 minutes thanks to those standard connectors they use. Contrast that with single face pallets where broken parts often require welding fixes that take much longer. Looking at what logistics companies actually report, these repairable features tend to keep pallets working properly for around three to five extra years before needing replacement. That makes a big difference over time in warehouse operations.

Operational Flexibility: Stacking, Nesting, and Automation Compatibility

Stacking and Racking Efficiency: Benefits of Double-Sided Symmetry

Double sided plastic pallets offer something special when it comes to storing goods vertically thanks to those matching decks on either side. When stuff is placed on these pallets, the weight spreads out pretty evenly between the two levels, which means they're less likely to tip over in those tall warehouse racks we see everywhere now. Unlike single face models that tend to have spots where things might give way under pressure, these double deckers create a solid base all around. Warehouse managers report being able to stack them safely as high as 12 meters in automated storage systems, though most stick to about 8-10 meters for extra safety margins. The testing labs back this up with their findings too.

Nesting Capabilities and Space Optimization in Return Logistics

Double face pallets when empty take up about 55% less room compared to their single face counterparts during transportation back to warehouses, which means trucks need almost half the space they normally would. The way these pallets lock together keeps them from moving around during transit, and they still have enough thickness in the walls to last through multiple trips something regular pallets just cant seem to pull off. Industry experts point out that this kind of efficient nesting makes all the difference in closed loop systems where every inch counts because saving space translates directly into lower fuel bills and reduced carbon footprints across the board.

Adoption in Automated Warehouses: Why Double Face Plastic Pallets Suit Smart Logistics

Double face plastic pallets have pretty good dimensional accuracy around ±1.2mm which works well with automated systems like robotic arms and conveyor belts. According to research from last year, warehouses switching to these plastic options saw about a third fewer alignment problems with their ASRS systems compared to when they used wooden pallets. The consistent shape and size of plastic pallets makes it much easier to work with RFID tracking technology something most modern warehouses really care about these days. Because they fit so well with automated processes, these pallets are becoming essential parts of smart logistics setups across many industries.

Cost, Sustainability, and Long-Term Value of Double Face Plastic Pallets

Upfront Cost vs. Long-Term Savings: ROI of Switching to Double Face Plastic Pallets

Double face plastic pallets do come with a price tag that's about 25 to 35 percent higher than regular single face ones at first glance. But when looking at the bigger picture, these plastic options last over a decade before needing replacement, which cuts down on replacements by roughly 60% according to an APAC study from 2023. Looking at recent findings from the 2024 Logistics Materials Report paints an interesting picture too. Companies actually start seeing returns on this extra spending within just two to three years because there's less product damage happening during transport (around 12% less compared to single face pallets) plus they save money since nobody has to spend time fixing damaged wooden pallets anymore.

Case Study: Beverage Distributor Cuts Replacement Costs With Double-Face Models

A 2023 trial with a European beverage distributor showed a 40% reduction in annual pallet replacement costs after switching to double-face plastic pallets. Broken pallet incidents fell from 12% to 2% of shipments, saving €18,000/year in product damage claims while improving cross-docking efficiency by 22%.

Environmental Impact: Recyclability and Reduced Carbon Footprint Through Reuse

Double-face construction enables 50% more reuse cycles than single-face pallets (APAC report 2023). Their 100% recyclability at end-of-life reduces landfill contributions by up to 8 tons annually for mid-sized distributors, with closed-loop recycling systems cutting lifecycle CO₂ emissions by 34% versus single-use wooden alternatives.

ESG Trends: How Corporate Sustainability Goals Favor Durable, Reusable Pallets

78% of supply chain managers now prioritize reusable packaging to meet ESG targets. Double-face plastic pallets' 15-year average service life supports circular economy initiatives, with 93% of surveyed manufacturers reporting improved sustainability metrics after adopting these platforms for automated warehouse systems.

FAQs

What is the main advantage of double face plastic pallets?

The primary advantage of double face plastic pallets lies in their twin deck design, which distributes weight across both decks, reducing point stress and increasing load capacity by up to 70% compared to single face pallets.

How do double face pallets enhance durability?

Double face pallets enhance durability through their use of HDPE mixed with UV stabilizers and slip-resistant additives, combined with interlocked molecular structures formed during molding, maintaining strength after multiple reuse cycles.

What are the environmental benefits of double face plastic pallets?

Double face plastic pallets offer environmental benefits through their 100% recyclability and ability to undergo 50% more reuse cycles than single face pallets, leading to reduced landfill contributions and carbon emissions.

Are double face plastic pallets suitable for light-duty use?

Despite their upfront cost premium, double face plastic pallets prove cost-effective even in light-duty scenarios due to their longevity and reduced replacement needs, saving costs in the long term.

Table of Contents

- Structural Design and Build: Double Face vs. Single-Face Plastic Pallets

- Load Capacity, Strength, and Performance Under Stress

- Durability, Lifespan, and Reusability in Industrial Applications

- Operational Flexibility: Stacking, Nesting, and Automation Compatibility

-

Cost, Sustainability, and Long-Term Value of Double Face Plastic Pallets

- Upfront Cost vs. Long-Term Savings: ROI of Switching to Double Face Plastic Pallets

- Case Study: Beverage Distributor Cuts Replacement Costs With Double-Face Models

- Environmental Impact: Recyclability and Reduced Carbon Footprint Through Reuse

- ESG Trends: How Corporate Sustainability Goals Favor Durable, Reusable Pallets

- FAQs