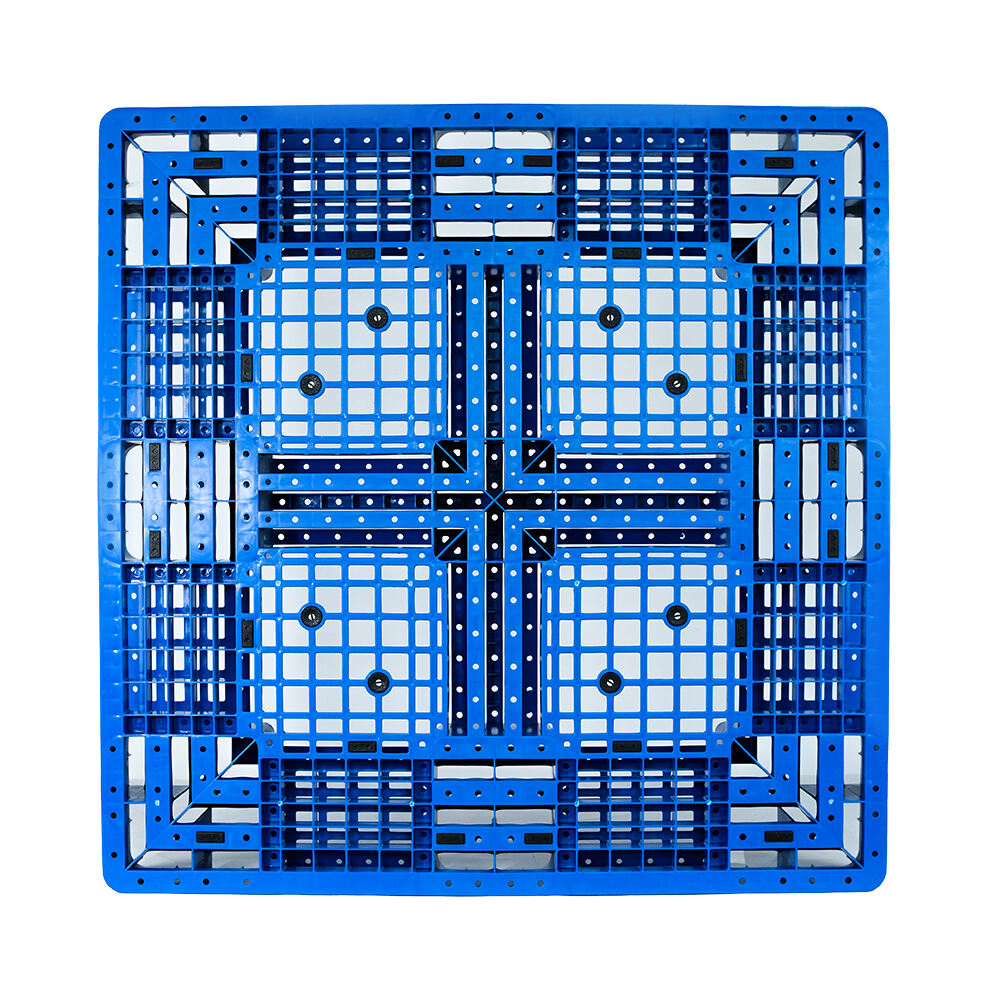

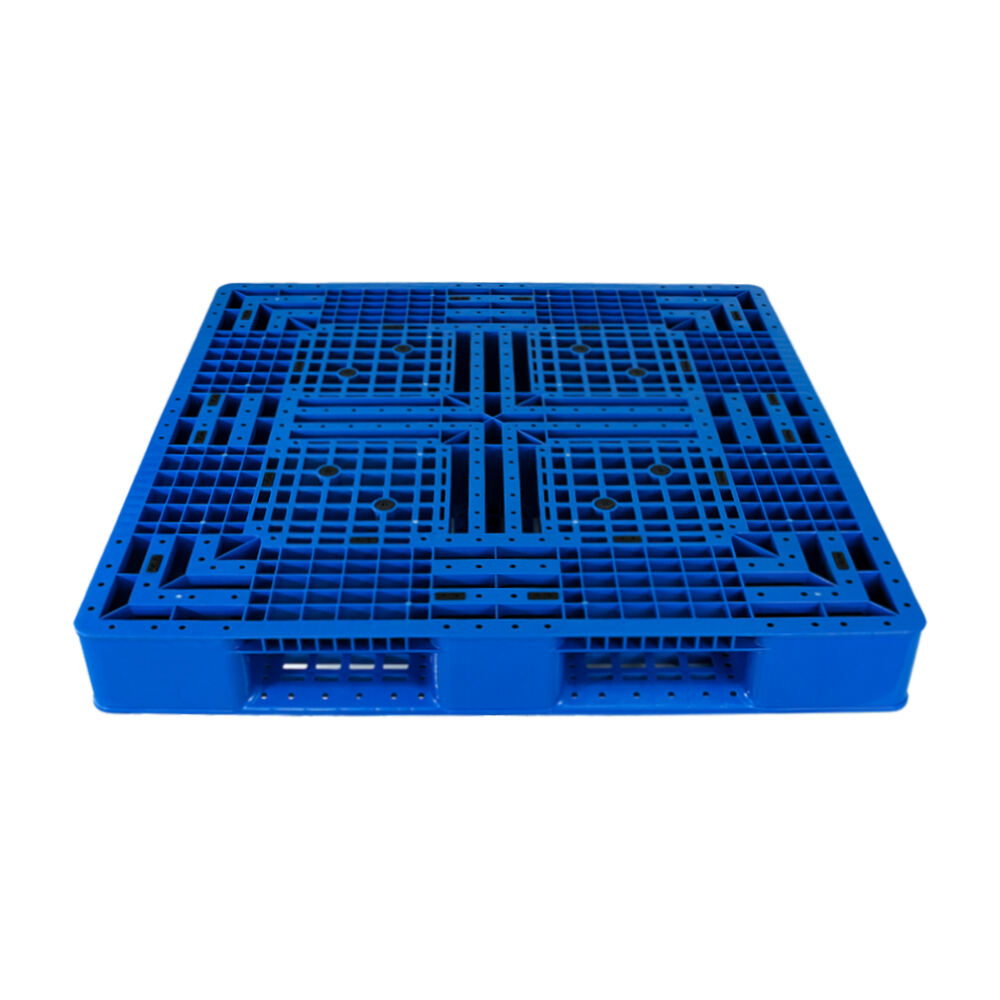

In today's globalized supply chains, the demand for custom stackable plastic pallets that precisely fit unique logistical footprints is paramount. Our expertise lies in engineering bespoke pallet solutions tailored to specific load dimensions, automation system requirements (such as conveyor widths or AS/RS compatibility), and industry regulations (including FDA, EU, or EPAL standards). Utilizing advanced 3D design and simulation tools alongside our fleet of over 300 injection molding machines, we translate client specifications into durable, high-performance pallets. Customization encompasses not just size, but also structural features like reinforced leg designs for racking, specific deck patterns (solid, perforated, or anti-slip), embedded RFID tags, and material selection for food safety or chemical resistance. Our in-house, professional pallet testing center rigorously validates every custom design for dynamic load capacity, stacking strength, and durability, ensuring the final product seamlessly integrates into your operation. By leveraging our five production bases and extensive manufacturing scale, we deliver these custom stackable plastic pallets with the efficiency and consistency of a standard product, providing a competitive edge in optimized space utilization and supply chain safety.